Best Practices for Maintenance, Cleaning, and Longevity

Electrophoresis units are the unsung workhorses of molecular biology and biochemistry labs, enabling scientists to separate and analyze nucleic acids and proteins with precision. Yet, despite their vital role, these instruments can suffer from performance issues, contamination, and even permanent damage if not cared for properly. In this comprehensive guide, we will explore the best practices for maintaining, cleaning, and troubleshooting your electrophoresis unit, ensuring it serves your research reliably for years to come.

Understanding Your Electrophoresis Unit

Before diving into care and maintenance, it’s essential to understand the basic components of an electrophoresis unit. Typically, a complete system includes:

- Electrophoresis tank or chamber: The main body where the gel and buffer reside.

- Gel tray and combs: Used for casting gels and creating wells for samples.

- Electrodes and wiring: Provide the electric current needed for molecule separation.

- Power supply: Regulates voltage and current through the system.

- Lid with safety interlock: Prevents accidental exposure to high voltage.

Proper care of each component is crucial for the unit’s performance and for laboratory safety.

General Maintenance: Keeping Your Unit in Top Shape

Regular maintenance is the foundation of a reliable electrophoresis system. Here are some general maintenance tips:

- Inspection: Before and after each use, visually inspect the tank, cables, electrodes, and gel trays for cracks, discoloration, or deposits. Pay close attention to delicate parts like connectors and seals that may degrade over time.

- Routine Checks: Test the functionality of the safety interlock on the lid and ensure the power supply displays and controls are responsive.

- Documentation: Maintain a log of usage, problems encountered, and maintenance performed. This record will be invaluable for troubleshooting and for scheduling preventative maintenance.

- Manufacturer’s Guidelines: Always consult and adhere to your unit’s manufacturer manual for specific maintenance intervals and recommendations.

Cleaning Your Electrophoresis Unit: Step-by-Step

Regular cleaning reduces contamination risks and prolongs the life of your equipment. Here’s a detailed cleaning routine:

1. Disassemble Safely

- Turn off and unplug the power supply before touching any part of the unit.

- Carefully remove the lid, gel tray, combs, and buffer chamber components.

2. Rinse Immediately

- Rinse the gel tray, chamber, and combs with deionized water immediately after use to prevent buffer residues and sample contamination from drying on surfaces.

- If your gel has leaked or spilled, clean up immediately to avoid corrosive buffer damage.

3. Gentle Cleaning Solutions

- For routine cleaning, use a mild lab detergent diluted in deionized water. Avoid abrasive cleaners, strong acids or bases, and organic solvents that may damage plastic components.

- Scrub gently with soft brushes or lint-free cloths, taking care not to scratch the transparent parts of the unit.

- Pay special attention to the grooves and crevices where gel and buffer residues tend to accumulate.

4. Rinse Thoroughly

- After cleaning with detergent, rinse all components thoroughly with deionized water to remove any residual cleaning agents that could interfere with future experiments.

5. Dry Completely

- Allow all parts to air dry fully before reassembling the unit. Avoid using heat sources, as excessive heat can warp plastic components.

- Store components in a clean, dust-free area to prevent contamination.

Special Care for Sensitive Components

Electrodes

- Electrodes are often made from platinum, gold, or stainless steel. Handle them with care, as damage or corrosion can affect the electric field and separation quality.

- Clean electrodes by rinsing thoroughly with deionized or distilled water after each use.

Power Cables and Connectors

- Inspect for frayed wires or loose connections. Replace damaged cables immediately to prevent safety hazards.

- Keep connectors dry and free of buffer or cleaning solution residue, which can lead to corrosion or short circuits.

Preventing Common Problems

Avoiding Buffer Crystallization and Residue Buildup

- Use fresh buffer for each run and avoid leaving buffer in the tank for extended periods, as it can crystallize and leave hard-to-remove deposits.

- After draining the buffer, rinse the chamber thoroughly with deionized water.

Preventing Leaks and Cracks

- Never use sharp objects or metal spatulas to remove gels, as this can scratch or crack the gel tray.

- Regularly check tanks and trays for hairline cracks. Replace any compromised components to prevent leaks and electrical hazards.

Reducing Risk of Electrical Hazards

- Ensure the tank is dry before operation, and never operate the unit with wet hands or standing water nearby.

- Always use the safety interlock lid and never override safety features.

- Label damaged units clearly and remove from service until repaired.

Long-Term Storage and Care

If your electrophoresis unit won’t be used for an extended period, follow these storage tips:

- Clean and dry all components thoroughly before storage.

- Disassemble and store small parts, like combs and trays, separately to prevent warping or pressure points.

- Keep the unit in a cool, dry area away from direct sunlight and sources of dust or chemical vapors.

Troubleshooting: When Things Go Wrong

Despite your best efforts, problems may still arise. Here are some issues and basic troubleshooting steps:

- Poor separation or smeared bands: Could be due to contaminated or degraded buffers, dirty gel trays, or damaged electrodes. Clean components, use fresh buffer, and replace faulty parts as needed.

- Current not flowing: Check that the power supply is working, cables are connected securely, and electrodes are clean and intact.

- Buffer leaks: Inspect for cracks in the chamber or gel tray, and replace as necessary.

- Corrosion or discoloration: Clean affected areas thoroughly and avoid using incompatible cleaning agents in the future.

Establishing a Maintenance Schedule

Develop a regular schedule for cleaning and checking your electrophoresis unit. This might include:

- Daily rinse and inspection after use.

- Weekly or biweekly deep cleaning, depending on frequency of use.

- Monthly checks of electrodes, wiring, and safety mechanisms.

- Annual review and possible replacement of worn parts.

Safety Considerations

Safety should always be a top priority:

- Wear appropriate PPE (lab coat, gloves, safety glasses) during cleaning and operation.

- Be mindful of electrical hazards—never bypass safety features.

- Dispose of gels, buffers, and cleaning waste in accordance with your institution’s environmental health and safety protocols.

Conclusion

An electrophoresis unit is a sophisticated piece of laboratory equipment that, with proper care, will deliver reliable results for years. By following a routine of inspection, cleaning, safe operation, and preventative maintenance, you not only protect your investment but also enhance the quality and consistency of your scientific work. Remember: a clean and well-maintained unit means safer experiments, clearer results, and fewer headaches for everyone in the lab.

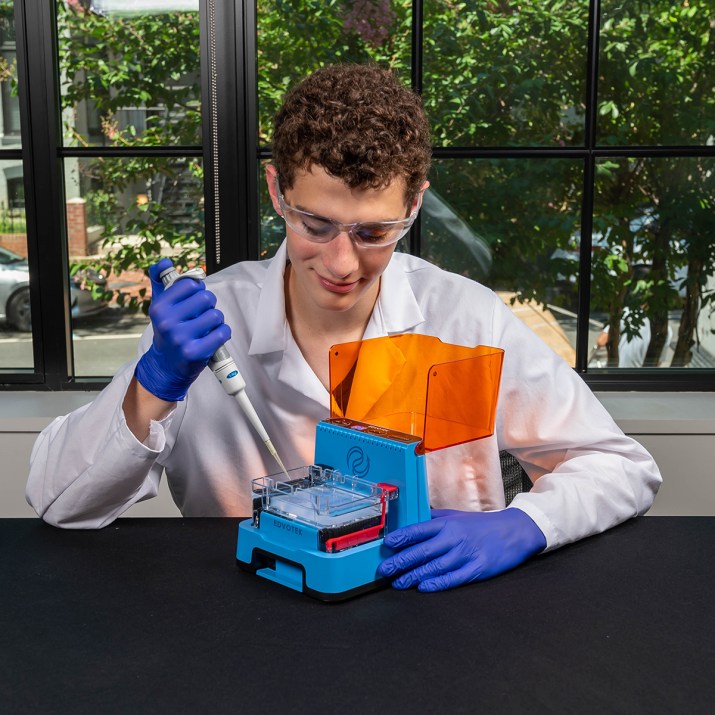

Interested in purchasing an electrophoresis unit for your classroom? You can find our MV10 Vertical protein electrophoresis unit here, our M12 classic DNA electrophoresis unit here, and my personal favorite, our state of the art EDGE Integrated Electrophoresis System right here. And as always, you can shop all of our equipment needed to set your class up for a successful school year at www.edvotek.com!